LC/DBM provides landscape contractors with Educational, Imaginative and Practical information about their business, their employees, their machines and their projects.

Issue link: https://landscapecontractor.epubxp.com/i/475699

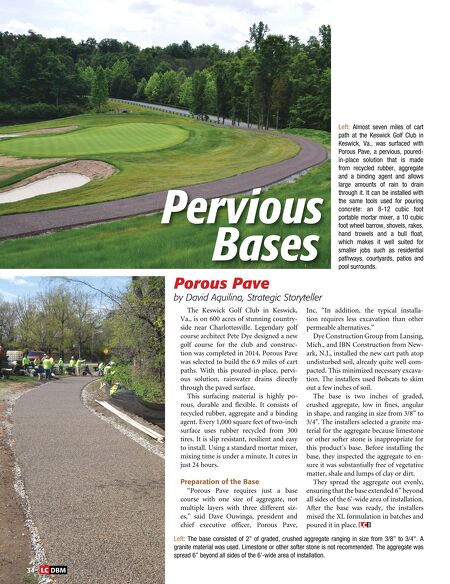

The Keswick Golf Club in Keswick, Va., is on 600 acres of stunning country- side near Charlottesville. Legendary golf course architect Pete Dye designed a new golf course for the club and construc- tion was completed in 2014. Porous Pave was selected to build the 6.9 miles of cart paths. With this poured-in-place, pervi- ous solution, rainwater drains directly through the paved surface. This surfacing material is highly po- rous, durable and flexible. It consists of recycled rubber, aggregate and a binding agent. Every 1,000 square feet of two-inch surface uses rubber recycled from 300 tires. It is slip resistant, resilient and easy to install. Using a standard mortar mixer, mixing time is under a minute. It cures in just 24 hours. Preparation of the Base "Porous Pave requires just a base course with one size of aggregate, not multiple layers with three different siz- es," said Dave Ouwinga, president and chief executive officer, Porous Pave, Inc. "In addition, the typical installa- tion requires less excavation than other permeable alternatives." Dye Construction Group from Lansing, Mich., and IBN Construction from New- ark, N.J., installed the new cart path atop undisturbed soil, already quite well com- pacted. This minimized necessary excava- tion. The installers used Bobcats to skim out a few inches of soil. The base is two inches of graded, crushed aggregate, low in fines, angular in shape, and ranging in size from 3/8" to 3/4". The installers selected a granite ma- terial for the aggregate because limestone or other softer stone is inappropriate for this product's base. Before installing the base, they inspected the aggregate to en- sure it was substantially free of vegetative matter, shale and lumps of clay or dirt. They spread the aggregate out evenly, ensuring that the base extended 6" beyond all sides of the 6'-wide area of installation. After the base was ready, the installers mixed the XL formulation in batches and poured it in place. Left: The base consisted of 2" of graded, crushed aggregate ranging in size from 3/8" to 3/4". A granite material was used. Limestone or other softer stone is not recommended. The aggregate was spread 6" beyond all sides of the 6'-wide area of installation. Left: Almost seven miles of cart path at the Keswick Golf Club in Keswick, Va., was surfaced with Porous Pave, a pervious, poured- in-place solution that is made from recycled rubber, aggregate and a binding agent and allows large amounts of rain to drain through it. It can be installed with the same tools used for pouring concrete: an 8-12 cubic foot portable mortar mixer, a 10 cubic foot wheel barrow, shovels, rakes, hand trowels and a bull float, which makes it well suited for smaller jobs such as residential pathways, courtyards, patios and pool surrounds. Pervious Bases Porous Pave by David Aquilina, Strategic Storyteller 34 LC DBM DBM LC